Product Highlights

- Apply to protect 4 cell Li-ion / Li-Polymer battery packs.

- Internally trimmed charge and discharge voltage limits.

- Discharge current limit detection.

Summarized Features and Benefits:

- Apply to protect 4 cell Li-ion / Li-Polymer battery packs.

- Internally trimmed charge and discharge voltage limits.

- Discharge current limit detection.

- Low current standby mode when cells are discharged.

- High quality and high yield: 100% tested before shipment.

- Compatible with both Li-ion and Li-Polymer cells.

Product Specifications:

| Item | Content | Criterion |

|---|---|---|

| Over Charge Protection |

|

|

| Over Discharge Protection |

|

|

| Over Current Protection |

|

|

| Short Protection |

|

|

| Resistance |

|

|

| Temperature |

|

|

| Dimension(L*W*T) | 37mm x 20mm x 3.4mm |

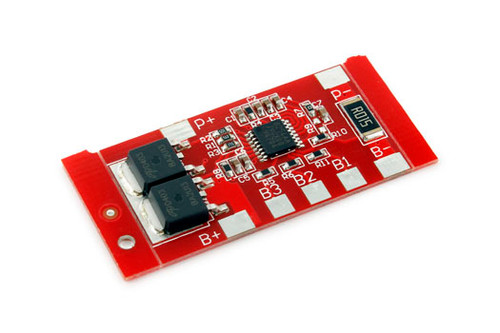

![Protection Circuit Module [PCB] for 33.3V (9S) Li-ion Battery Pack (Working 5A, Cutoff 10A)](https://cdn11.bigcommerce.com/s-g2o7t0ov4m/images/stencil/500x659/products/1036/1022/32130_front_x350__81117.1581955439.jpg?c=2)

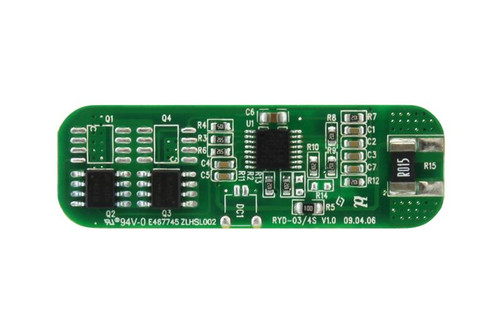

![Protection Circuit Module [PCB] for 14.4V/14.8V (4S) Li-ion Battery Packs (Working 10A, Cutoff 40A)](https://cdn11.bigcommerce.com/s-g2o7t0ov4m/images/stencil/500x659/products/1018/1006/32176_frontcopy__25707.1581940188.jpg?c=2)